Professional Analysis: Process Deconstruction and Industrial Code of Precision Replica Watches

2025-02-08

In the field of mechanical watches, the ultimate pursuit of craftsmanship and industrialized precision manufacturing have always been the core proposition of the industry. This article deeply analyzes the manufacturing logic of high-end replica watches from three dimensions: parts, movements, and assembly processes, and explores the technical boundaries of "craftsmanship replication" in the industrial age.

I. Material Science: Metallurgical Development from 316L to 904L.

The skeleton components of modern fashion watches have formed a standardized system:

316L steel: Standard for basic models, wear resistance meets daily wear requirements, hardness HRC 25-30, and requires PVD coating to achieve mirror polishing effect.

904L steel: Patented steel of brands such as Rolex, nickel-chromium content increased to 23%/20%, anti-sensitivity increased by 300% compared to 316L, glass degree after polishing can reach more than 98°, but the tool wear rate increases by 40%.

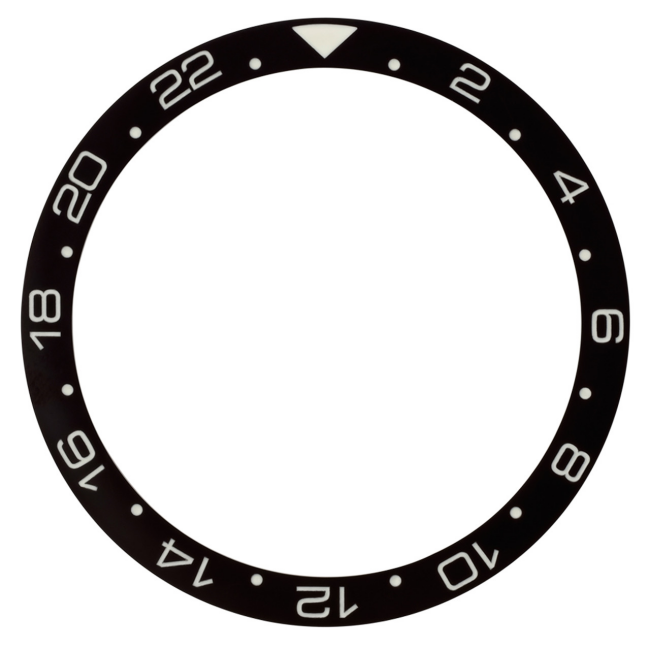

Ceramic bezel: Using ZrO2 (coke oxidation) high temperature sintering, Mohs hardness reaches 8.5, laser polishing depth needs to be controlled at 0.15mm±0.02mm pallet belt.

Technical breakthrough.

High-precision CNC lathes (such as Swiss STUDER S33) have achieved 0.001mm level processing accuracy, but the sticking characteristics of 904L still rely on technical experience to adjust cutting parameters, which is one of the core barriers to counterfeiting technology.

Second, movement architecture: Swiss ETA and Asian customization game.

1. Swiss movement.

ETA 2824-2: 28,800 vibration frequency, 38 hours of power reserve, 127 parts, 4.6mm thickness.

ETA 2892-A2: ultra-thin structure (3.6mm), end point automatic winding efficiency increased to 82%.

Difficulty in imitation: heat treatment process of barrel spring (Rockwell hardness HRC 52-54), grinding accuracy of escape wheel shaft tip diameter 0.08mm.

2. Asian movement.

Seagull ST2130: Benchmarked against ETA 2824, the frequency deviation is controlled at ±5 seconds/day.

Dandong 4130: Titanium movement, the clearance between the column wheel and the vertical clutch structure is ≤0.03mm.

Cost control: Laser processing is used to replace traditional hollow patterns, and the production cost of a single movement is reduced by 60%.

III. Assembly process: Micrometer war under the microscope.

1. Hand system.

- Second hand shaft hole matching tolerance: ≤0.005mm.

- Luminous filling (Super-LumiNova C3): coating thickness 0.12mm, shrinkage rate after curing 2.7%.

2. Waterproof structure.

- Screw-in crown: thread pitch 0.35mm, tightening drawing 0.6N·m

- Pneumatic air valve: automatically triggers pressure relief when pressure difference > 3ATM, the elastic coefficient of the precision spring needs to undergo 72 hours aging test.

3. Surface treatment.

- Wire drawing process: 1200 mesh tungsten steel grinding wheel, cutting speed 15cm/min.

- Electroplating layer: thickness 2μm, current density needs to be stable at 1.2A/dm²

Fourth, the ethical dilemma of industrialized production.

There are currently two types of products on the market:

Regular replicas: innovations based on the original movement architecture, such as increasing the power reserve to 72 hours.

1:1 clone: 97% similarity of appearance parts is achieved through 3D laser mapping, but set in heat treatment process and assembly accuracy, movement bearings are usually 60% of the original parts.

From the perspective of technical ethics, we advocate the "craft tribute" mode - extracting the engineering wisdom of classic design and combining modern materials science for innovative iteration. For example, the use of grade 5 titanium alloy case (density 4.5g/cm3) to reconstruct the structure of the diving watch in the 1960s not only retains the aesthetic genes, but also achieves a technological breakthrough of 30% weight reduction.

Conclusion

Watchmaking is a representative of precision mechanical engineering, and is also an eternal game between artistic aesthetics and industrial rationality. In the era of industrialization 4.0, the true technological evolution does not lie in the simple replication of classics, but in the soul of mechanical watchmaking with technological innovation.